Cnc Laser Cutting Fundamentals Explained

Wiki Article

In terms of present day manufacturing, the precision and performance of laser slicing know-how are actually match-transforming. Laser reducing equipment have revolutionized industries by offering a method of slicing components with unparalleled precision. Should you’ve ever marveled for the intricate patterns on metallic or questioned how complex designs are produced so seamlessly, it’s typically the perform of the industrial laser reducing equipment.

Let’s begin with the basic principles: a laser cutter is really a Resource that uses a laser beam to chop materials. This beam is amazingly concentrated and generates higher temperatures to soften or vaporize the fabric, producing exact cuts. Unlike standard procedures, which might use mechanical blades, a laser cutter offers a standard of precision that is nearly unmatched. Think about endeavoring to carve a delicate sample which has a hammer—clearly, a laser cutter is a great deal a lot more refined!

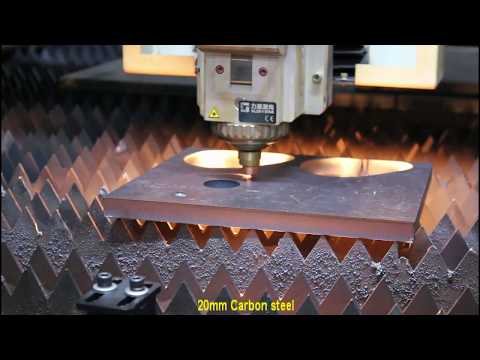

Industrial laser slicing takes this engineering to the subsequent stage, furnishing options for big-scale functions. These equipment are crafted to take care of significant materials and higher creation volumes, guaranteeing that even the most demanding tasks are accomplished with large effectiveness. Consider it since the difference between using a precision knife for sensitive paper crafts and a powerful saw for cutting via thick wood.

The Facts About Laser Cutting Machine Uncovered

On the globe of CNC laser chopping, the “CNC” means Computer system Numerical Control. This technological innovation allows for automatic and really exact cuts by subsequent electronic designs. If you’ve at any time utilised a computer to attract after which you can witnessed that drawing come to life, CNC laser slicing operates in an analogous way, translating electronic patterns into physical cuts. It’s like using a virtual designer with the precision of the laser.

On the globe of CNC laser chopping, the “CNC” means Computer system Numerical Control. This technological innovation allows for automatic and really exact cuts by subsequent electronic designs. If you’ve at any time utilised a computer to attract after which you can witnessed that drawing come to life, CNC laser slicing operates in an analogous way, translating electronic patterns into physical cuts. It’s like using a virtual designer with the precision of the laser.Cnc Laser Cutting Things To Know Before You Buy

Precision laser reducing is just not nearly creating cuts; it’s about making them right each and every time. The laser is often modified to realize various depths and widths, ensuring that each Minimize is precisely exactly where it must be. This really is very important for apps in which even a slight deviation could lead to significant challenges. Imagine it being a surgeon’s scalpel, exactly where precision is not merely critical but Totally critical.

Precision laser reducing is just not nearly creating cuts; it’s about making them right each and every time. The laser is often modified to realize various depths and widths, ensuring that each Minimize is precisely exactly where it must be. This really is very important for apps in which even a slight deviation could lead to significant challenges. Imagine it being a surgeon’s scalpel, exactly where precision is not merely critical but Totally critical.Laser slicing tools is available in different forms, Each individual customized to particular desires. No matter if you need a compact desktop model for passion tasks or a huge industrial machine for manufacturing facility use, there’s a laser cutting Resolution available for yourself. These machines range in energy, pace, and abilities, so it’s vital that you pick the right one particular for your personal certain software.

Sheet metallic laser cutters certainly are a Exclusive category of laser reducing equipment designed specifically for slicing metallic sheets. They are broadly Utilized in industries starting from automotive to aerospace due to their capability to take care of metallic with precision and velocity. Picture a sheet of metal just like a blank canvas, plus the laser cutter given that the artist who creates sophisticated and exquisite designs with remarkable precision.

Laser cutting solutions are One more critical element of this technological know-how. Not everyone needs to invest in their particular laser reducing machine, especially if they only want occasional cuts or lack the Area for this kind of equipment. Numerous businesses offer laser chopping products and services in which you can send out your models and also have them Minimize with large precision. It’s like outsourcing your artwork to a skilled Expert.

Laser cutting systems combine several parts to deliver the desired success. Within the laser supply for the reducing mattress, as well as Regulate application, each and every A part of the procedure will work collectively to ensure a flawless Procedure. It’s somewhat similar to a symphony orchestra, wherever Just about every musician has a particular role, and only by Performing collectively do they create a harmonious general performance.

In relation to laser cutting know-how, the evolution is immediate and amazing. Initially utilised mainly for slicing metals, these devices now cope with an array of products like plastics, Wooden, and in some cases fabrics. This flexibility helps make laser chopping engineering a precious tool in many industries. Visualize possessing a Swiss Military knife view full story that can manage approximately any materials—That is what fashionable laser cutting technological innovation presents.

The precision of laser cutting machines is truly remarkable. They're able to Slice materials to inside microns in the meant layout, guaranteeing that even probably the most intricate specifics are preserved. This standard of precision is especially important in industries where exact measurements are essential. Consider it because the difference between a tailor-made fit and off-the-rack apparel—the in shape is just best whenever.

Excitement About Laser Cutting Machine

One more benefit of laser reducing know-how is its efficiency. Not like traditional reducing procedures that might call for various techniques or applications, laser reducing generally completes the task in one go. This not simply hastens manufacturing and also reduces materials waste. It’s like using a superior-speed teach that will get you to the desired destination quickly and effectively with no unneeded stops.During the context of industrial purposes, the robustness of laser cutting machines is vital. These devices are created to endure the calls for of ongoing Procedure, generally jogging 24/seven in significant-quantity configurations. Their toughness makes explore now certain dependable overall performance and reliability, that's essential for preserving creation schedules. It’s like possessing a large-duty truck that reliably delivers merchandise working day immediately after working day.

One of several impressive facets of laser cutting is its ability to deliver clean up and exact edges. This decreases the need for write-up-processing, for instance sanding or ending, which can be time-consuming and dear. The end result can be a smooth, concluded product or service That usually requires negligible added function. Imagine ending a craft undertaking with no glue spills or tough edges—it’s that thoroughly clean!